A cryogenic medical refrigerator is a specialized refrigeration unit designed to preserve biological samples, vaccines, pharmaceutical products, and medical materials at ultra-low temperatures. These units ensure product stability, prevent degradation, and maintain the integrity of sensitive samples over long periods.

ULT Freezer-60°C(Vertical) Manufacturer

We use imported compressors and fans to ensure precise temperature control of the equipment. Compared with the -86 series, this series of -60 degrees has a low unit price but stable performance. If you only need -60 to preserve your samples, this series is a good choice.

Zhejiang Heli Refrigeration Equipment Co., Ltd. owns a 25,000-square-meter modern industrial park, featuring a scientific layout and comprehensive functions. The company has established a full-chain industrial system covering technological R&D to finished product inspection, which provides a solid guarantee for the high-quality production of ultra-low temperature refrigeration equipment.

-

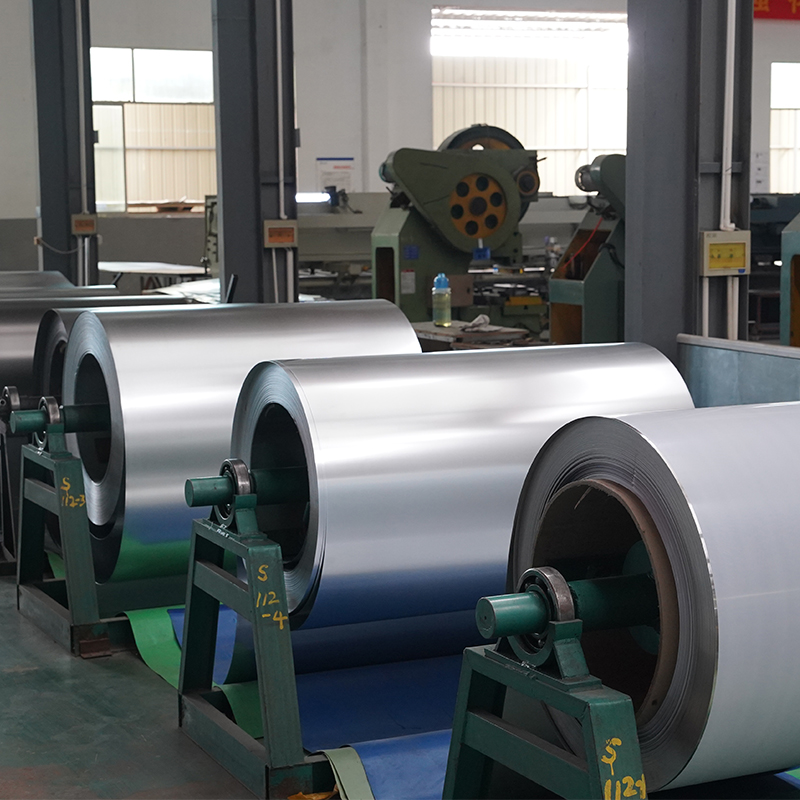

High quality raw materials

High quality raw materialsWe use high-quality raw materials, which are reliable and durable in quality.

-

OEM/ODM

OEM/ODMWe have a professional R&D team that can design products according to different needs.

-

Rich experience

Rich experienceWe have a professional technical team that can improve the process based on the different characteristics of the products to extend their service life.

-

Quality inspection

Quality inspectionThe quality inspection room is equipped with advanced quality inspection devices. Before each refrigerator is dispatched, it needs to undergo various tests to ensure its stability and reliability.

Q. 1. What is a cryogenic medical refrigerator?

Q. 2. What temperature ranges do your refrigerators cover?

Our product line includes models with various temperature capabilities:

•Pharmaceutical refrigerators: +2°C to +8°C

•Low-temperature freezers: down to –45°C or –60°C

•Ultra-low temperature freezers: –86°C

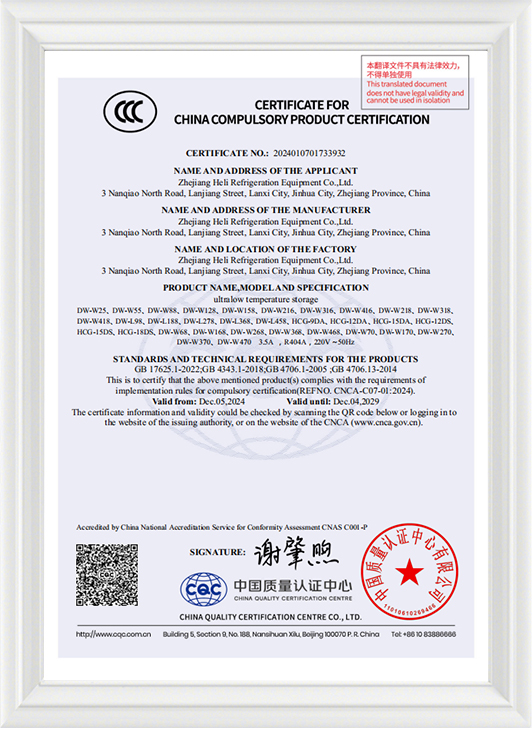

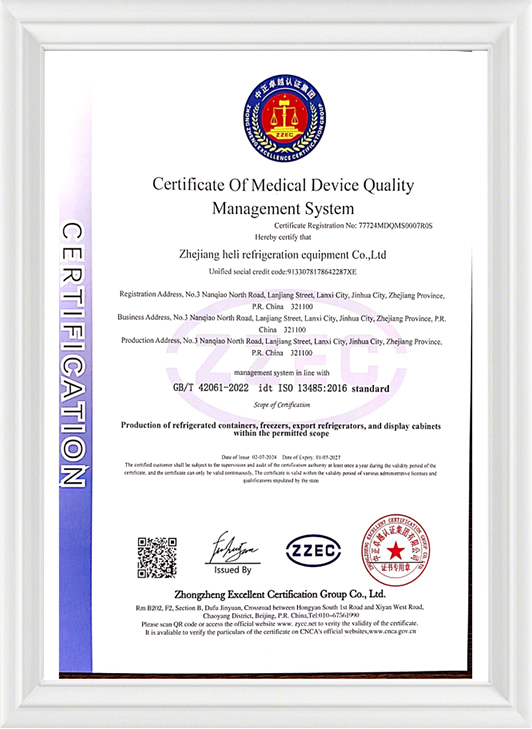

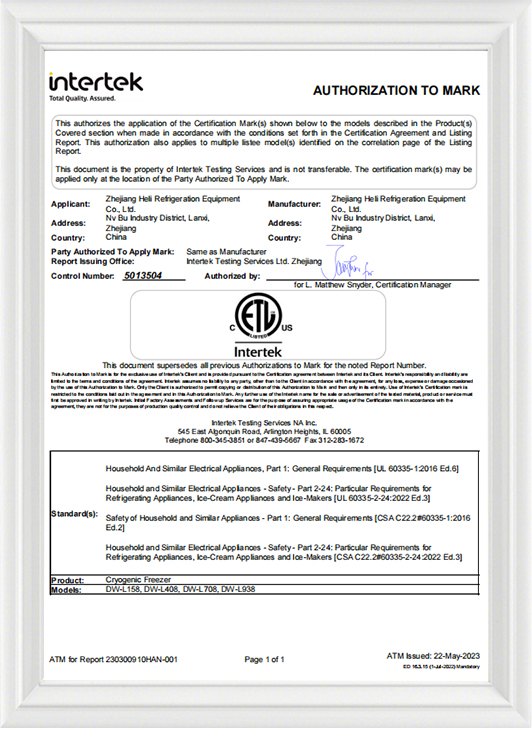

•Cryogenic freezers: as low as –150°CQ. 3. What safety and quality certifications do your refrigerators have?

Our products are manufactured in accordance with international standards and can be supplied with certifications such as FDA CE, ISO 13485, and ISO 9001. Each unit undergoes rigorous performance testing, quality inspection, and temperature calibration before delivery.

Q. 4. How do you ensure temperature accuracy and reliability?

Each model is equipped with a high-precision digital temperature control system, real-time monitoring sensors, and audible/visual alarm functions to detect temperature deviations. Optional data logging and remote monitoring systems are available for enhanced safety and traceability.

Q. 5. Can the refrigerators be customized to meet specific requirements?

Yes. We offer customization options for capacity, interior configuration, voltage, and monitoring systems. Custom branding, data interfaces, and alternative refrigerants (environmentally friendly options) can also be provided upon request.

Q. 6. Do you provide international shipping and after-sales service?

Yes. We export globally and work with logistics partners experienced in handling precision laboratory equipment. Our technical team provides remote support, spare parts, and professional guidance for installation and maintenance.

Q. 7. What are the maintenance requirements for cryogenic refrigerators?

Routine maintenance includes cleaning condenser filters, verifying temperature uniformity, and periodically checking door seals. Our after-sales team can provide maintenance guidelines and technical training for your staff to ensure optimal performance and longevity.

Q. 8. How can I choose the right model for my application?

Our sales engineers will assist you in evaluating your storage requirements — such as temperature range, sample volume, installation space, and power configuration — to recommend the most suitable model for your application.

Q. 9. Do you work with distributors or OEM partners?

Yes. We welcome collaboration with qualified distributors and OEM partners worldwide. We provide full technical support, marketing materials, and training to help our partners serve their markets effectively.

-

Ensuring proper handling and transport of an upright ultra low freezer is a key concern for labs and facilities that need to relocate equipment, move samples be...

READ MORE -

For many research facilities and medical labs, an ultra cold storage freezer is more than just equipment — it’s the cornerstone of long‑term sample preservation...

READ MORE -

A ultra cold storage freezer is a cornerstone of many laboratories, biobanks, and medical facilities — but real-world experience shows that not all units perfo...

READ MORE -

When managing critical biological materials, having a stable ultra cold storage freezer is essential for preserving sensitive samples over long periods. Likewis...

READ MORE

中文简体

中文简体 English

English Français

Français عربى

عربى